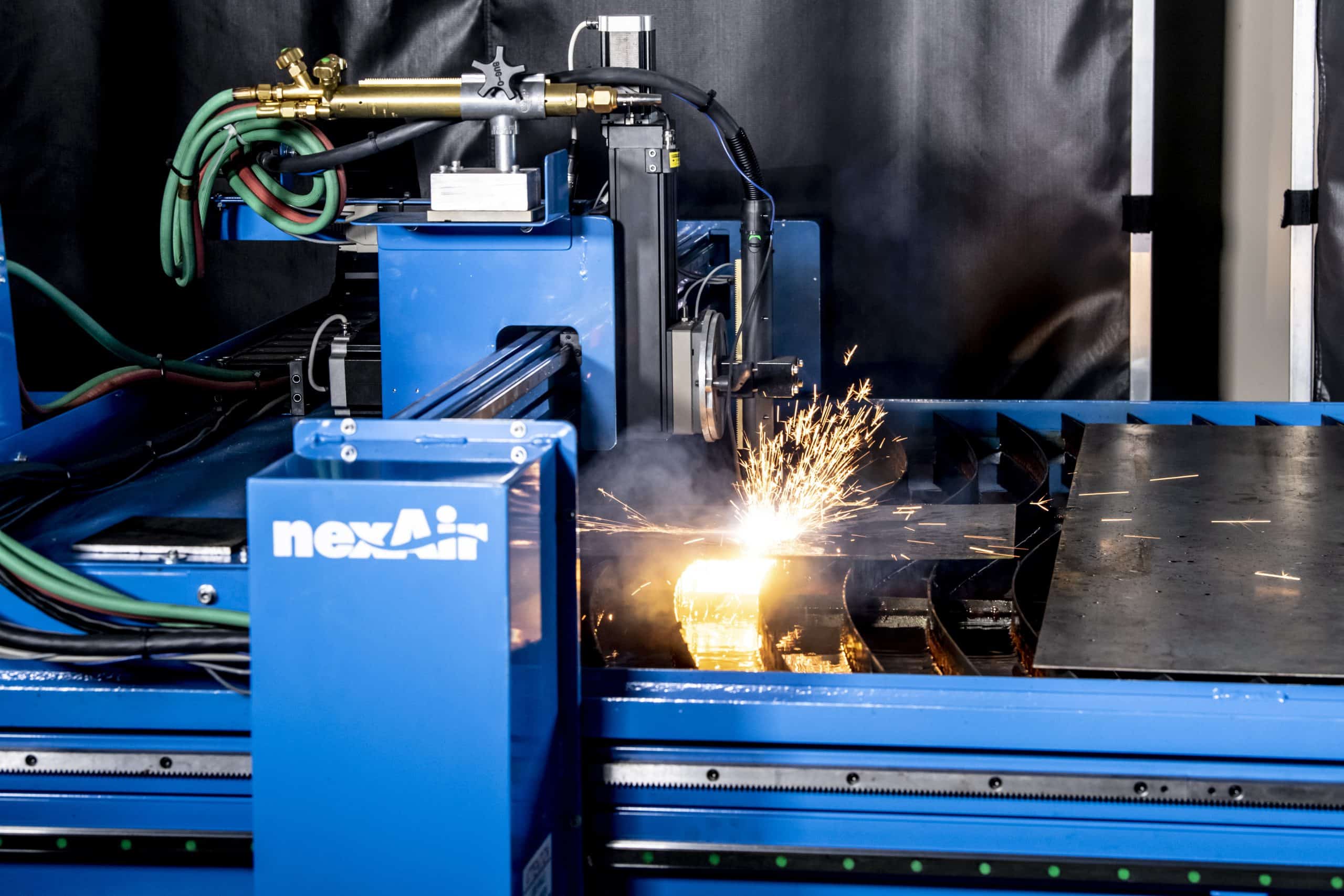

Breaking through the capacity ceilings of traditional manufacturing can be achieved by embracing welding automation. This transformation is not only about augmenting productivity but also about revolutionizing product design, enhancing the role of welders, and leveraging data for continuous improvement. Let’s explore how welding automation creates new opportunities and addresses existing challenges in manufacturing.

Enhancing Manufacturing Efficiency with Automation

Traditional manufacturing methods often hit capacity ceilings, limited by space, equipment, and available skilled labor. The demands of increasing output can strain resources and budgets. By integrating automated welding solutions into production, companies can streamline operations.

Automated systems can replace multiple manual stations, reducing the need for supervision and eliminating downtime related to human fatigue. In facilities where space is a premium, the compact footprint of robotic welding systems allows for increased production without physical expansion. This approach leads to consistent quality, eliminating the drift seen when manual welders tire.

New Possibilities for Product Design

Automation offers the flexibility to execute complex welding tasks that aren’t feasible manually. Continuous welds, precise heat control, and intricate pattern replication are all possible with advanced technologies like laser welding robots. This capability fosters innovative product designs that enhance both performance and visual appeal.

Welding automation enables engineers and designers to push boundaries, creating single-piece assemblies from what would traditionally be multiple components. These advancements bolster product differentiation in the market, supported by the efficient use of cobot welding tools, which offer versatility across a variety of materials.

Welding Careers in the Automation Era

The advent of welding automation does not signify the end of welding careers; it signals a transformation. The focus shifts from direct labor to roles centered on managing technology, such as programming robots and developing welding automation solutions. This evolution creates enriched career paths that attract new talent.

Experienced welders can utilize their knowledge of materials and welding processes to contribute to successful automation projects. By integrating traditional skills with modern technologies, welders enhance the implementation of automated production lines and maintain oversight to ensure quality systems.

Leveraging Data for Continuous Improvement

Automation technologies capture comprehensive data, including current, voltage, and travel speed, offering insights unavailable from manual methods. This information can be analyzed to uncover patterns and improvement opportunities, supporting ongoing optimization of the welding automation process.

Frequently Asked Questions

What is the role of a welder in an automated system?

In automated systems, welders often transition to roles focused on programming and maintaining robotic systems, leveraging their expertise to oversee quality and optimize processes.

How does welding automation affect production capacity?

By integrating welding automation, manufacturers can replace multiple manual tasks with efficient automated systems, significantly increasing production capacity without expanding physical space.

Can welding automation improve product design capabilities?

Yes, welding automation allows for complex design implementations not feasible with manual welding, enabling new product features and improved performance.

In summary, welding automation is a transformative force in manufacturing, offering efficiency improvements, new design possibilities, enriched career paths, and data-driven insights. By considering the transition to automated systems, manufacturers can unlock new levels of performance and innovation.