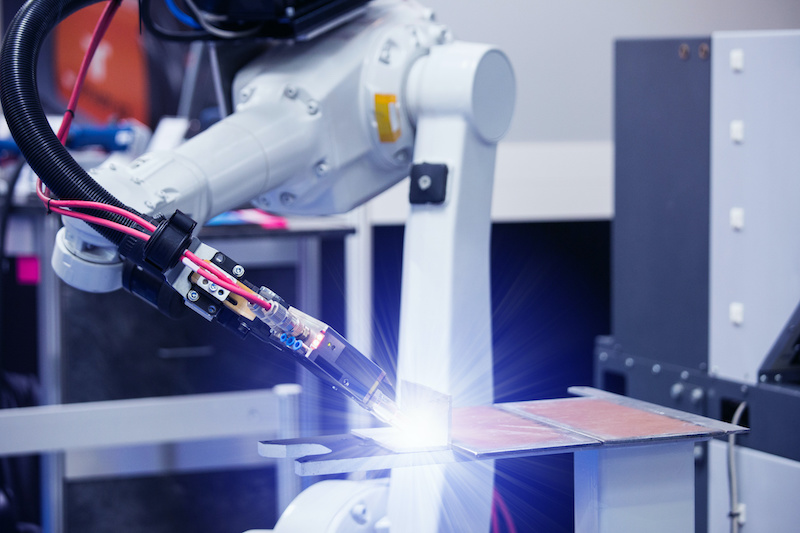

Automatic Welding

Can robots replace welders? Is welding automation the way forward?

The answer to this is yes. The reality of the matter is that there is a shortage of welders in the world. The United States alone has a shortage of about 80,000 welders. Even the markets in the United Kingdom and India have a similar situation. This is the main reason why companies turn to automated welding solutions.

To give you a better understanding of this, let’s talk about how welding automation works. The most common forms of automation are robot welding, robotic welding, semi-automated and fully automated. The first thing to understand is that welding robots are machines that are designed to weld metal pieces together. Some of them are designed to do specific welding processes such as Gas Metal Arc Welding (GMAW), Gas Tungsten Arc Welding (GTAW), and Metal Inert Gas Welding (MIG). The second type is robotic welding.